Mastery in Semiconductor Manufacturing

We bring Mastery to Semiconductor Manufacturing.

We take responsibility for the successful results of a Fab, with our proven holistic knowledge, methods and experience proven in 31 waferfabs

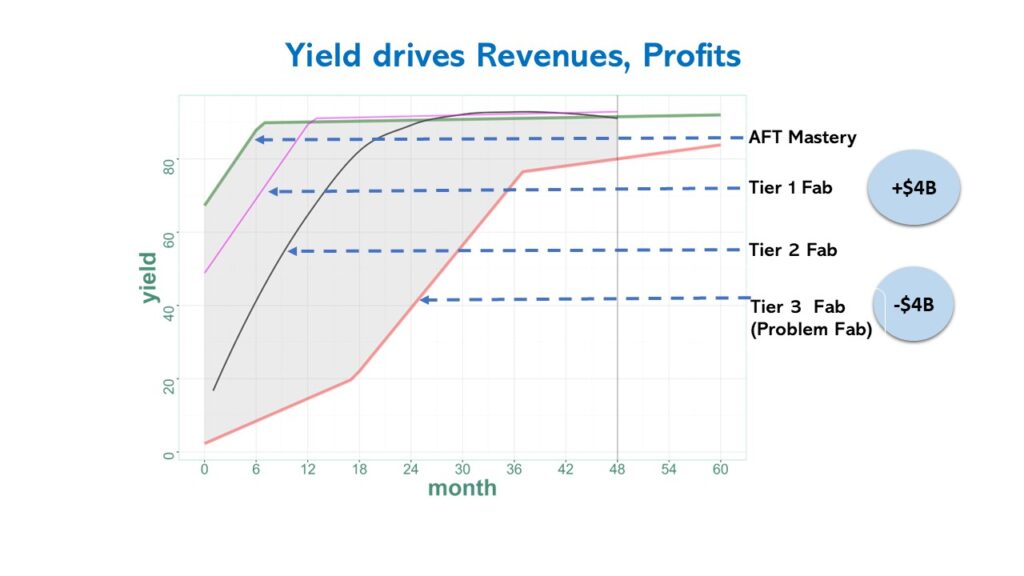

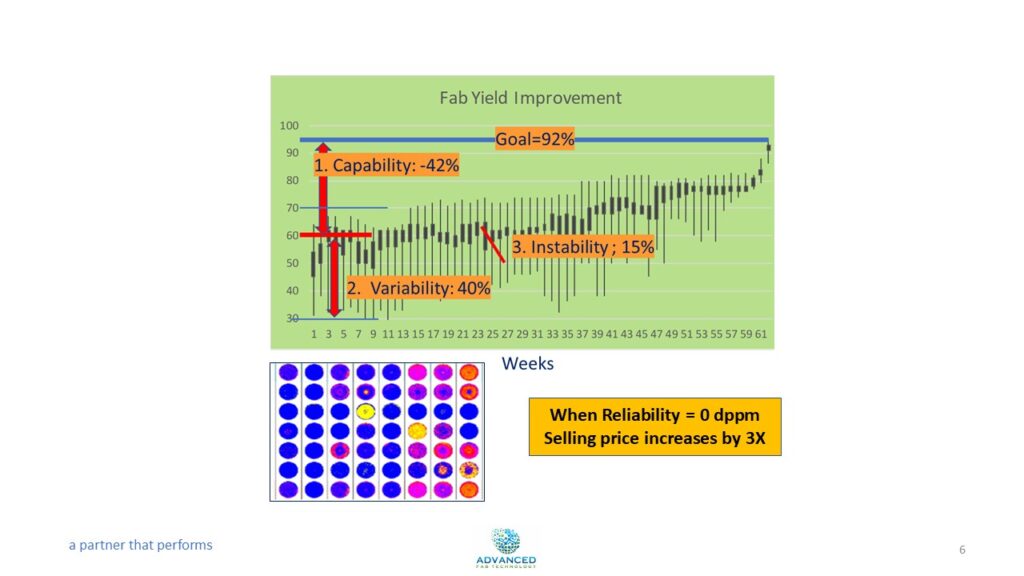

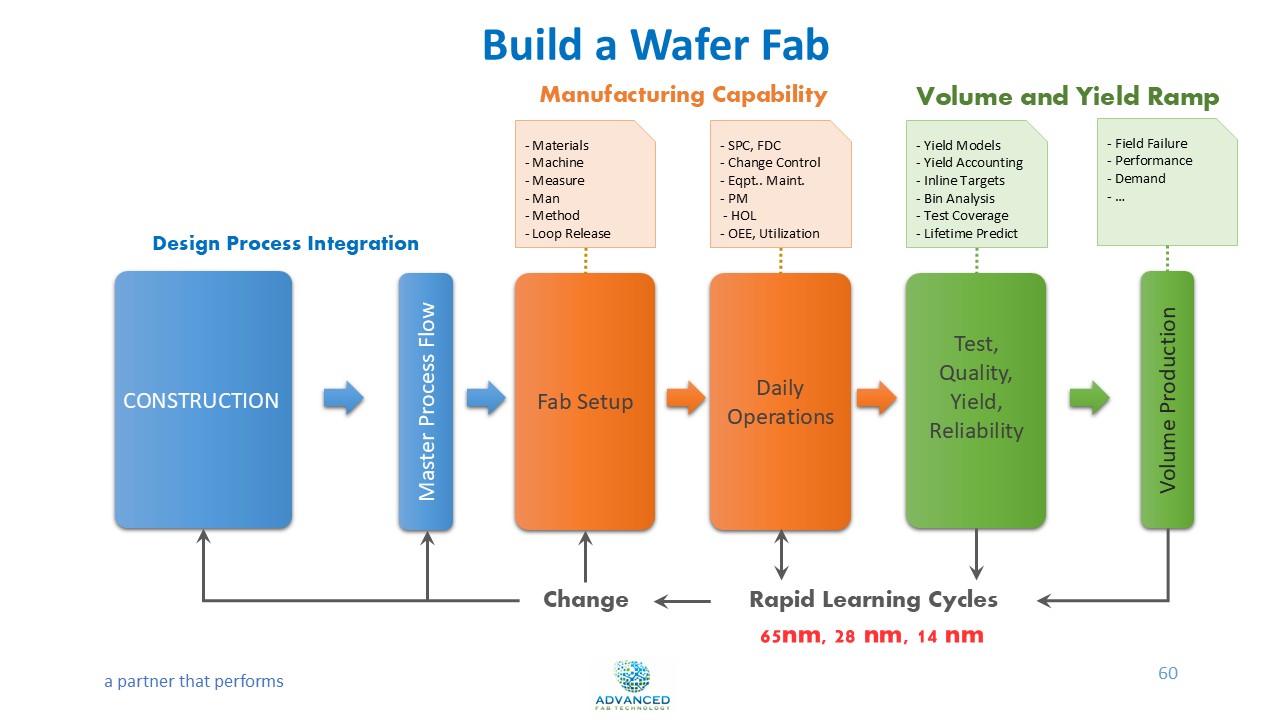

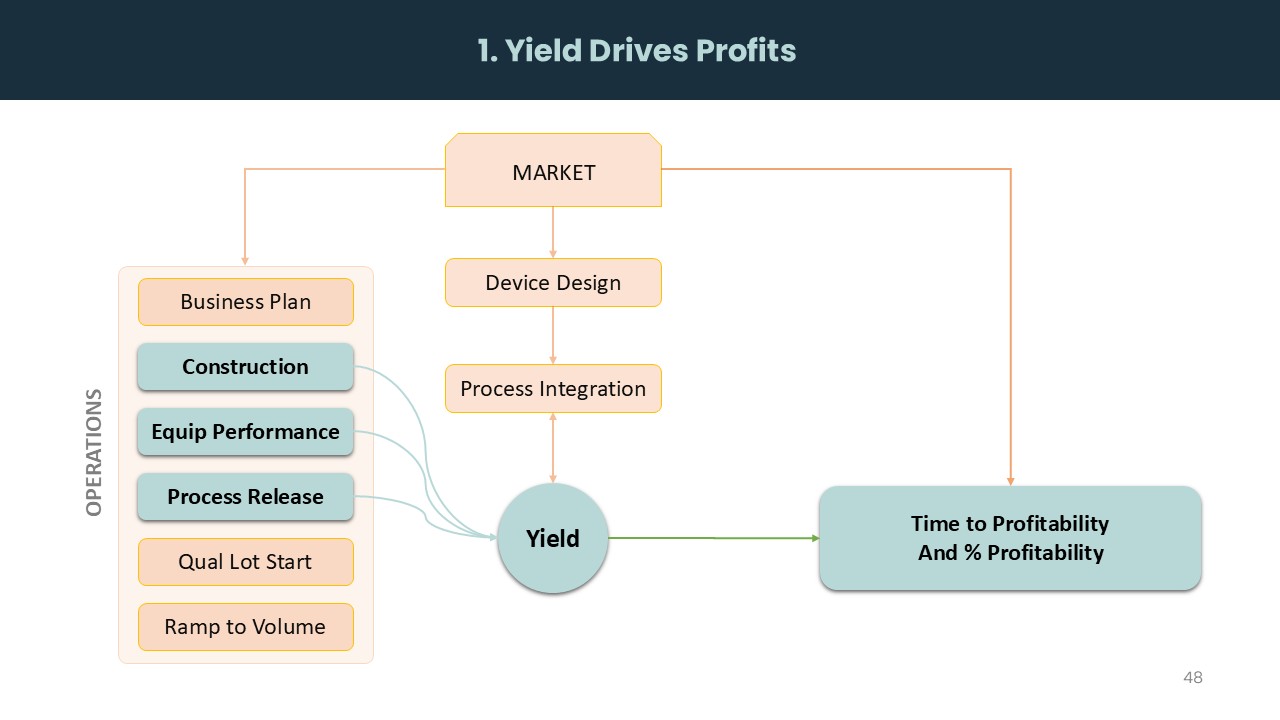

Fabs needlessly must have a learning curve. This is dangerous as results are unforgiving and glaring. Losses are in years and billions or profit margins are poor.

About Us

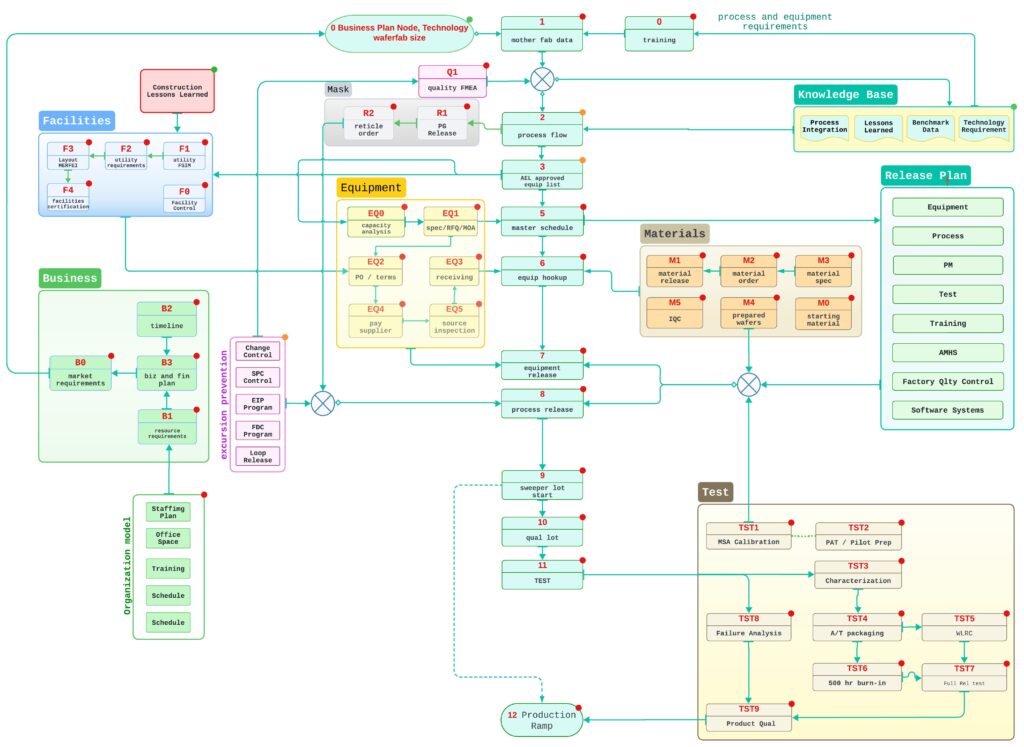

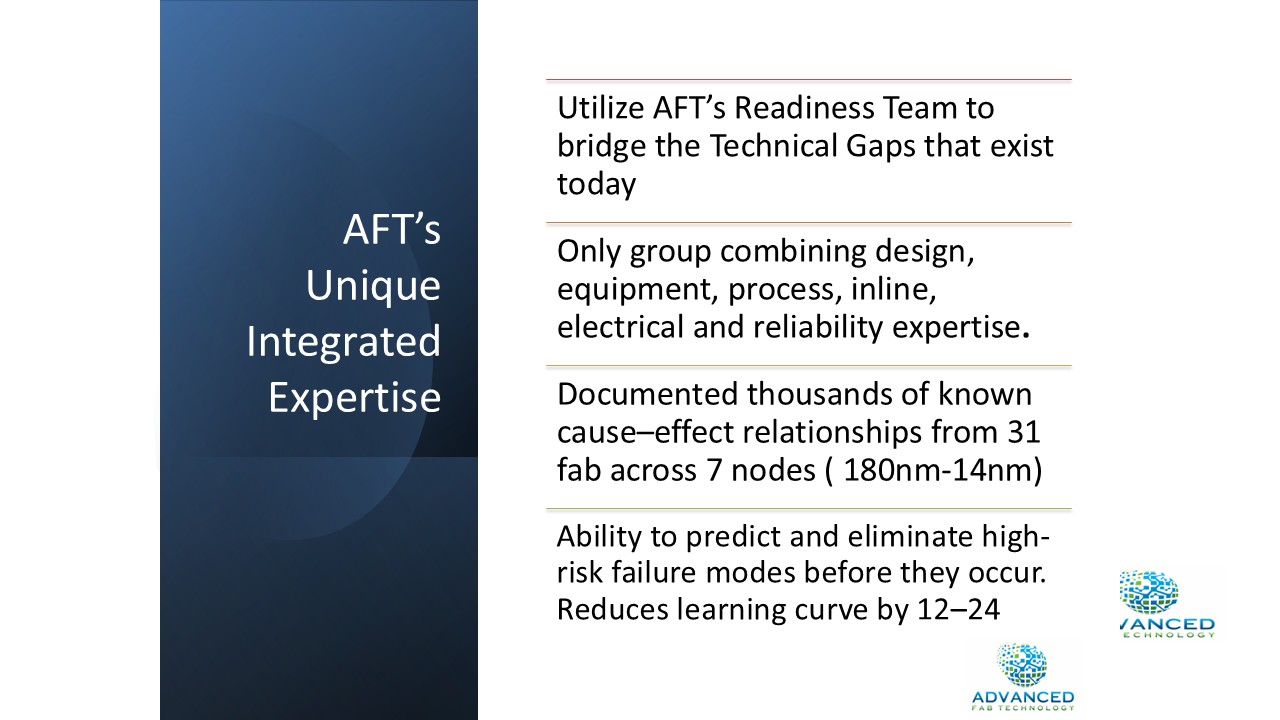

Our core team of experts with over 30 years of proven semiconductor manufacturing experience, empowers wafer fabs to achieve world-class mastery through our disciplined proprietary methodology in all (18) functions of a fab

Rooted in deep scientific and engineering practical knowledge, this approach preempts failures at every equipment and process and delivers unprecedented yield and profitability in 3 learning cycles, surpassing industry leaders like TSMC and Samsung.

Patrick leads the team. He is a veteran with decades at Texas Instruments, PDF Solutions, and Applied Materials

“Our strategy ensures accountability for wafer fab results. By systematically eliminating the failures accumulated across 31 fabs over the past 30 years, success is inevitable.”

Services

- Training Engineers, Managers and Executives

- Fab Startup

- Technology Transfer

- New Technology Readiness

- Rapid Yield Enhancement

- Ramp Readiness

- Equipment Yield Service Training

- FDC: Third Leg of the Waferfab

- Fab Assessment

- Infrastructure Readiness

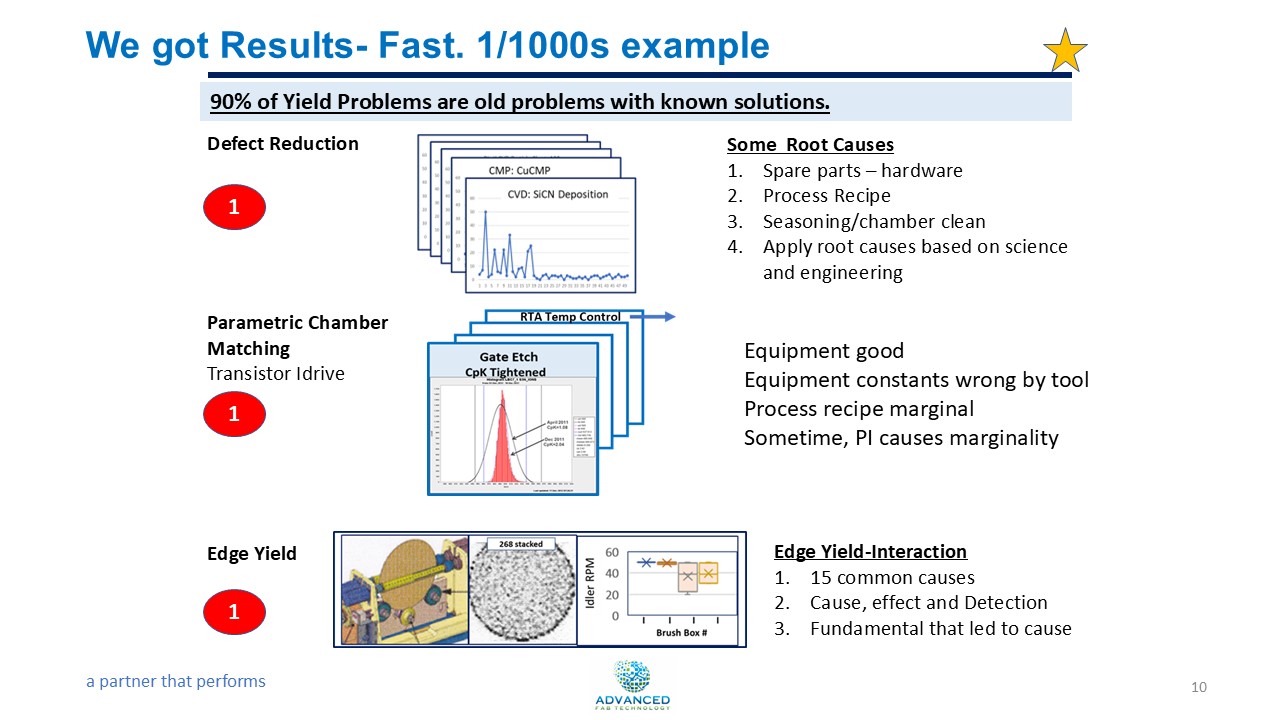

ROOT CAUSES

Wafers are processed correctly yet the final test results are poor

Turns out, from 31 fab data that 83% of all yield, profitablity, shipments and Reliablity are due to equipment issues (subset of materials and process)

PITFALLS

Losses mount to $ 2 Million /day for 28nm Logic, CEOs are fired and layoffs occur.

. The underlying problem is that the right and necessary information often is unobserved, unrecognized, or insufficient to prevent problems that have already been solved

Work Experience

Summary:

With my 40-year experience in Semiconductor Manufacturing, I developed a proven record, second to none, Fab Startup, Yield, time-to-first revenue and break even

- Texas Instruments: 30 years of manufacturing, development, startups, technology transfer

- Consultancy: 10 years: PDF Solutions and Applied Materials, Advanced Fab Technology

- Government of India Advisory committee for Semiconductor Manufacturing

Highlight:

- Improvement a fab (28nm, 50,000 wspm) by $ 800 Million/year

- Improve time-to-market by 1 year or $ 2.2 Billion

- 7 new fab startups

- 12 technology transfers

- 7 Technology nodes

Miniline Installation Tasks

- 12 Yield Enhancement

- 30 years at Texas Instrument

Place Holder

Place Holder

Place Holder

My Portfolio

What My Clients Says

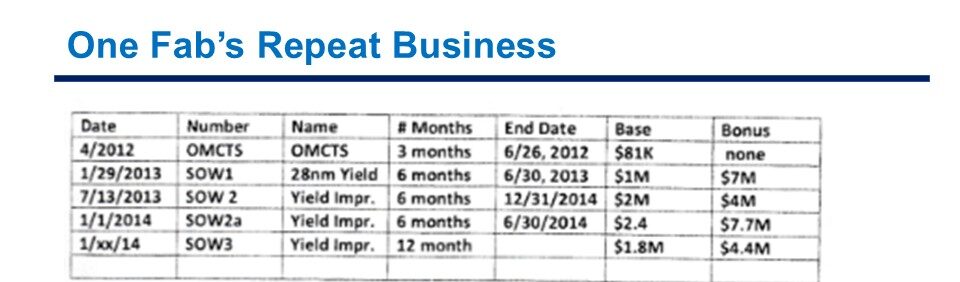

Come back / Significant Repeat Business

Julie England: Awesome job on yield readiness with respect defect density and yield; no debate. Overall, I have to tell you one of the reasons we received the Sun award is C035.B yield ahead of plan. And for that, you can be very proud. Thanks & regards, Julie

VP Program Manager for Sun Microsystems

Tom Weichel: Patrick, I like this. Have you been sending this format all along? I like to see a dashboard of metrics, so I know what to focus on for New Technology Development success

Howard Tigelaar: In my view what was done differently on C035.B that enabled the success was new methodologies introduced by Patrick and me and outstanding execution by the fab process engineering team…. – rgds, Howard

Stan Ashburn – RE: Hello world from Gemini): Patrick, Laura, and Readiness Team, a large part of this success is due to you and the Readiness team’s coordination of ensuring the process readiness for 1st pass success. Thank you for your support to the C035.C program. Regards, Stan